Earlier in my career, I was part of an internal consulting organization in JP Morgan Chase. While my team was focused on developing advanced analytics and machine learning solutions, I also got a lot of exposure to the work of teams that focused on Continuous Improvement.

Two of the biggest things I learned from this exposure was how to lead effective change management (using the Adkar model), and how principles of Lean Agile can be applied in business operations. These lessons stuck with me, and are part of the reason I’ve had so much success building and leading high-performing teams.

But In the fast-evolving world of IT operations, agility, reliability, and efficiency are more crucial than ever.

As IT teams strive to deliver services faster, with higher quality and lower costs, looking outside the traditional IT playbook can offer powerful insights. One such source of wisdom is the Toyota Production System (TPS)—a manufacturing philosophy that revolutionized automotive production and inspired global movements like Lean and Agile. I first became exposed to this in my work at Chase, and despite its industrial roots, TPS holds invaluable lessons for IT operations in how to manage complexity, reduce waste, and continuously improve.

What is the Toyota Production System?

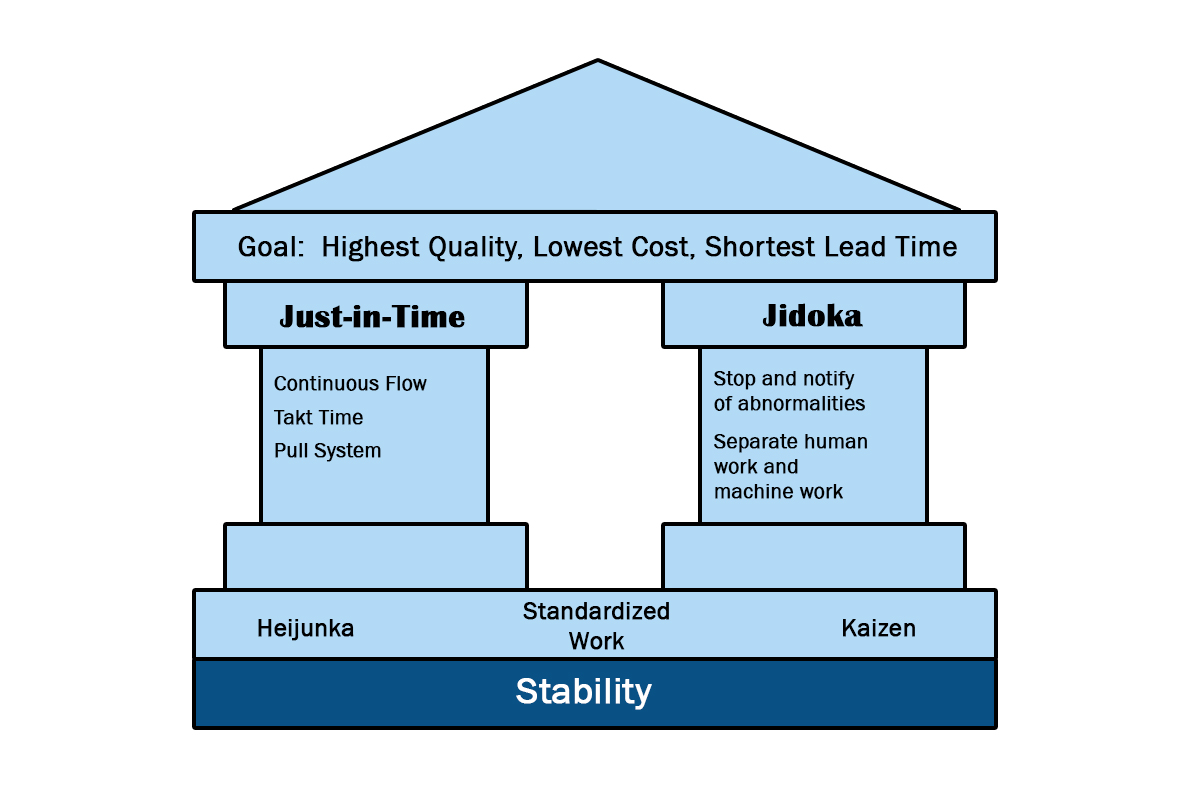

Developed by Toyota in the mid-20th century, TPS is a comprehensive approach to manufacturing that focuses on eliminating waste, improving quality, and maximizing efficiency. It’s the blueprint behind Toyota’s remarkable consistency in producing high-quality vehicles at scale. TPS is grounded in two foundational pillars:

- Just-In-Time (JIT) – Producing only what is needed, when it is needed, and in the amount needed.

- Jidoka (Automation with a Human Touch) – Stopping work when a problem occurs to prevent defects and empower workers to fix issues.

In addition to these pillars, TPS embodies several core principles that guide its practice:

- Kaizen (Continuous Improvement): Everyone in the organization is responsible for finding and implementing improvements.

- Respect for People: Empowering and trusting workers to make decisions and solve problems.

- Standardized Work: Defining and adhering to best practices while allowing for evolution.

- Heijunka (Level Production): Smoothing out work to reduce variability.

- Elimination of Muda (Waste): Identifying and removing activities that do not add value.

Applying TPS Principles to IT Operations

Although TPS originated in manufacturing, its core principles translate remarkably well to IT operations. Here’s how IT teams can apply the TPS mindset to enhance performance, reliability, and responsiveness.

Just-In-Time (JIT): Optimize Workflows and Resource Allocation

In manufacturing, JIT ensures inventory arrives exactly when needed, minimizing overproduction and storage costs. In IT operations, JIT can be reflected in:

- Demand-driven provisioning: Automatically scaling infrastructure (e.g., cloud resources) based on real-time demand, avoiding over- or under-provisioning.

- Agile incident response: Triggering workflows or scripts only when specific thresholds are breached, ensuring teams focus on the most relevant tasks.

- Kanban boards and Work-In-Progress (WIP) limits: Visualizing tasks and limiting concurrent work to prevent overload and inefficiencies.

By adopting JIT principles, IT teams can reduce the clutter of unnecessary processes and focus on delivering value when and where it’s needed.

Jidoka: Build Quality into the Process

Jidoka means that any team member—or machine—can stop the production line when a defect is detected. In IT, this translates to automated quality checks and empowering teams to respond to issues early.

Applications include:

- Automated monitoring and alerting: Systems should automatically detect anomalies (e.g., service degradation, security breaches) and trigger alerts or corrective actions.

- Shift-left testing: Embedding quality checks early in the software development lifecycle (e.g., during code commits or CI/CD pipelines).

- Error budgets and SLOs (Service Level Objectives): Letting teams control deployments and rollbacks based on agreed service levels, allowing quick remediation when issues arise.

This proactive approach prevents defects from cascading into major incidents and builds resilience into IT operations.

Kaizen: Foster a Culture of Continuous Improvement

Kaizen is about making small, incremental improvements every day. For IT operations, fostering a Kaizen mindset involves:

- Post-incident reviews (blameless retrospectives): After an incident, analyze what happened, why it happened, and how it can be prevented in the future.

- Feedback loops: Implementing regular check-ins and reviews of processes, tool effectiveness, and team dynamics.

- Encouraging experimentation: Giving teams time and freedom to innovate on tooling, automation, and workflows.

By continuously refining operations, IT teams can become more adaptive and prevent small issues from becoming chronic inefficiencies.

Standardized Work: Create Consistency Without Rigidity

Standardization in TPS ensures that tasks are performed the best-known way every time. In IT operations, this principle supports:

- Runbooks and SOPs (Standard Operating Procedures): Clearly documented procedures for common tasks (e.g., system restarts, backup protocols) that ensure reliability and reduce onboarding time.

- Infrastructure as Code (IaC): Codifying infrastructure deployment and configuration to ensure repeatability and reduce human error.

- Playbooks for incident response: Structured guides that help teams triage and resolve issues in a consistent and predictable manner.

Standardized work reduces variability, accelerates troubleshooting, and forms a foundation for automation.

Heijunka: Balance Workloads and Reduce Volatility

Heijunka aims to level out production schedules to prevent bottlenecks and overburden. In IT operations, this principle supports:

- Load balancing and auto-scaling: Dynamically distributing system traffic to avoid spikes and downtime.

- Smoothing deployment schedules: Releasing changes in smaller, more frequent batches instead of large, risky deployments.

- Capacity planning: Proactively forecasting resource needs based on trends and historical data to prevent system overloads.

Leveling demand and output helps IT teams remain stable even during periods of high stress or unexpected incidents.

Eliminate Muda: Identify and Remove Waste

Muda refers to any activity that doesn’t add value. In IT operations, common forms of waste include:

- Manual, repetitive tasks: These are ripe for automation (e.g., log rotation, server patching).

- Overprocessing: Running unnecessary scripts or collecting excessive metrics that aren’t used.

- Waiting and delays: Long review queues, change approvals, or incident escalations.

- Context switching: Multitasking across too many tools or projects, which reduces focus and efficiency.

A continuous effort to identify and eliminate waste enables teams to free up time for higher-value work.

An operation is an operation

The Toyota Production System may have started on the factory floor, but its principles are profoundly relevant to today’s IT landscape. By embracing JIT, Jidoka, Kaizen, and other TPS tenets, IT operations can achieve greater agility, resilience, and clarity. The key lies in adapting its mindset of relentless improvement, respect for people, and pursuit of value.

In a digital world where change is constant and complexity is growing, the timeless wisdom of TPS offers IT leaders a proven framework for building better systems. I may have first learned these tenets in their application to banking operations, I still use them often today in my current work as a cloud infrastructure operations leader.

If you want to discuss this topic more, please get in touch either below in the comments or send me a message!

Leland4164

Good information and explaination

Chris

Thank you! Was there anything specific that jumped out at you here? Do you use any of these in your management?